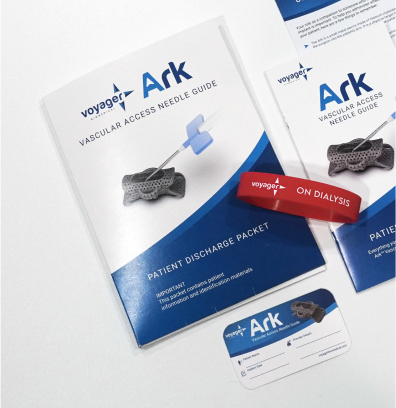

THE POWER OF GOOD DESIGN

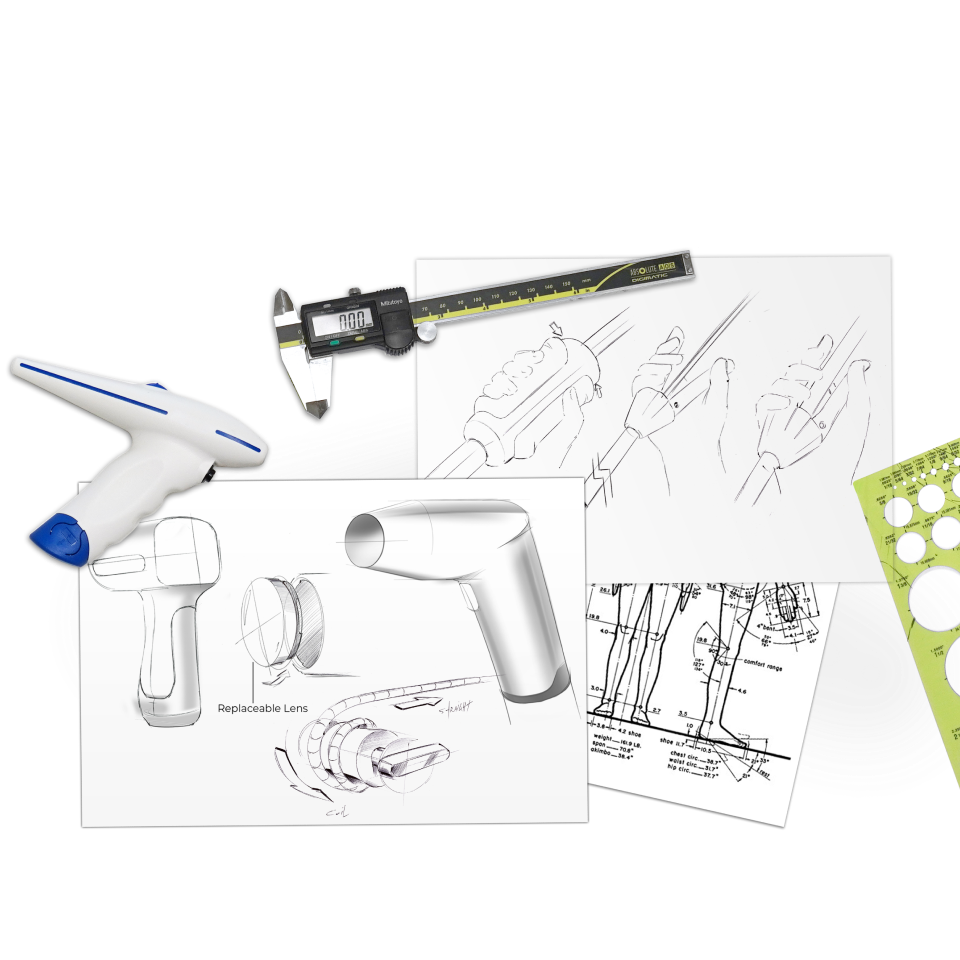

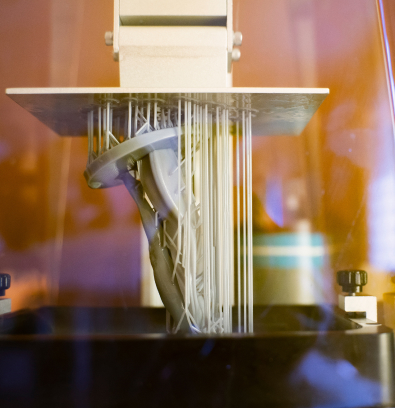

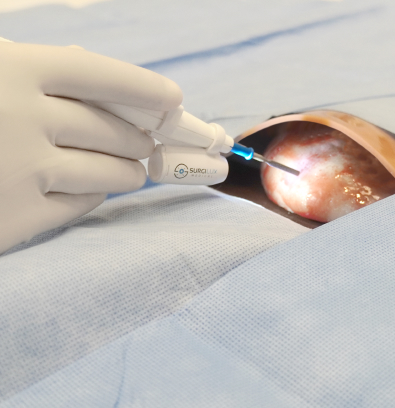

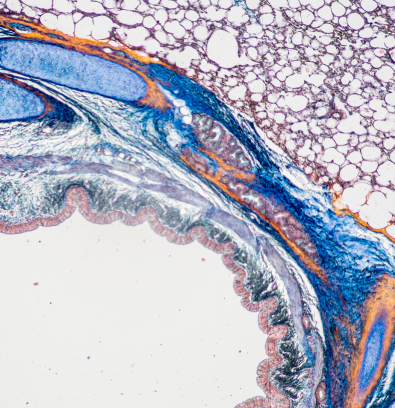

INNOVATION AND EXPERTISE CREATE INFINITE POSSIBILITIES

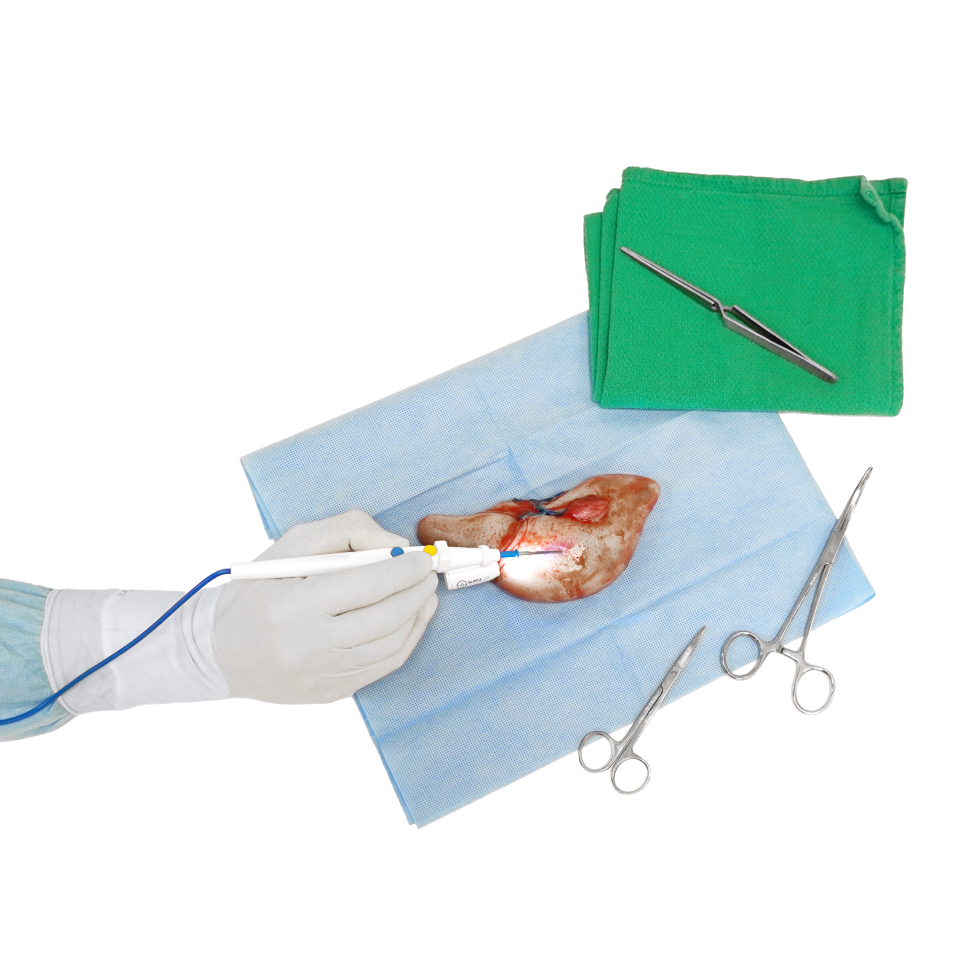

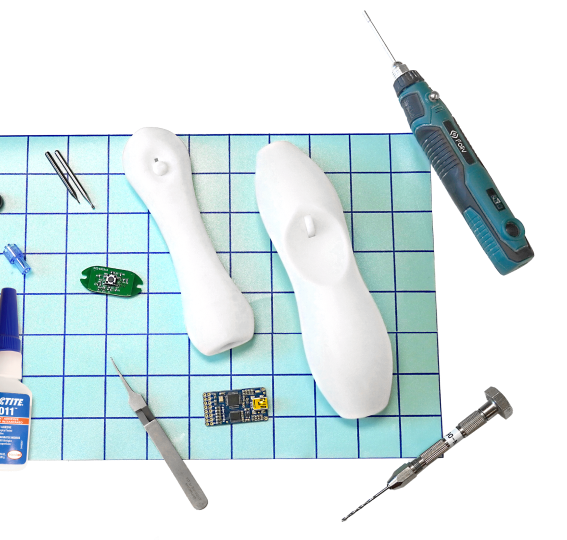

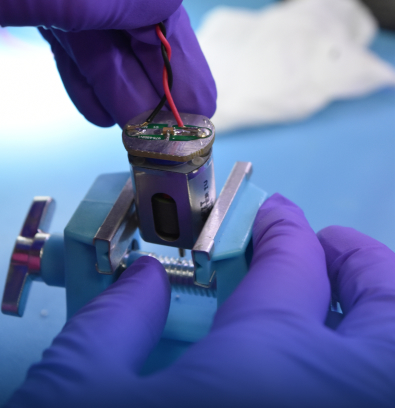

We collaborate with physicians, founders, innovators, and medical experts to bring value through design. Your idea, combined with our strategy, can result in diverse solutions with concrete outputs you can incorporate into your next stage of development.